Surface Mount / AOI / X-Ray

Using GSC’s SMT fixtures provides a multitude of benefits during the screen printing, placement and reflow operations during the SMT process. Today’s marketplace demands that PCB’s become smaller and more densely packed with components. Our SMT tooling responds to these ever increasing requirements by helping make your SMT operations more highly reliable and cost effective.

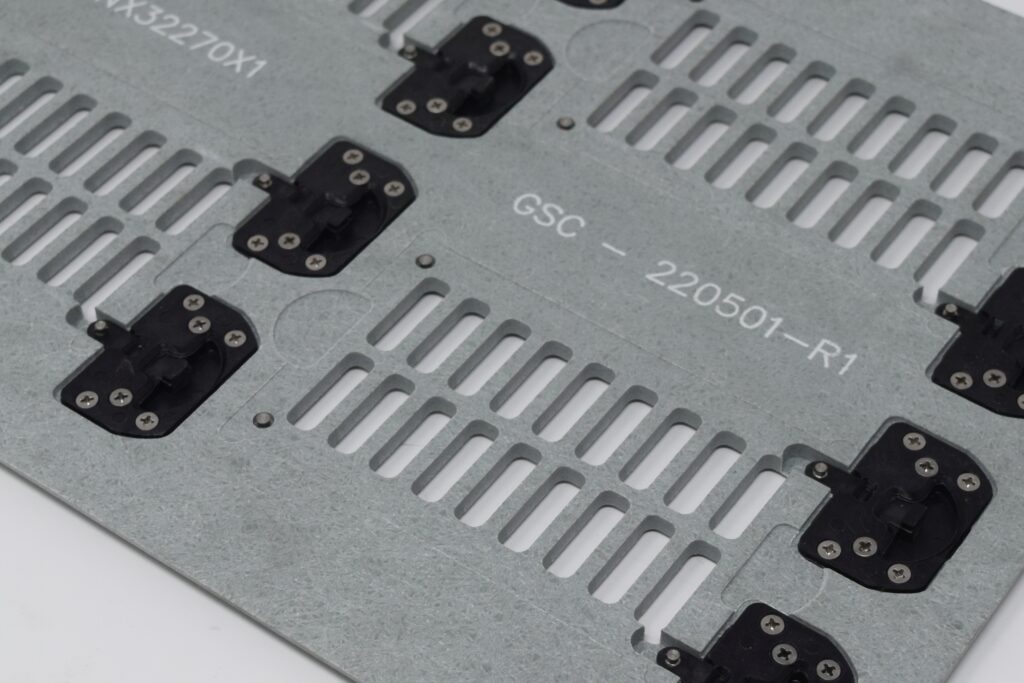

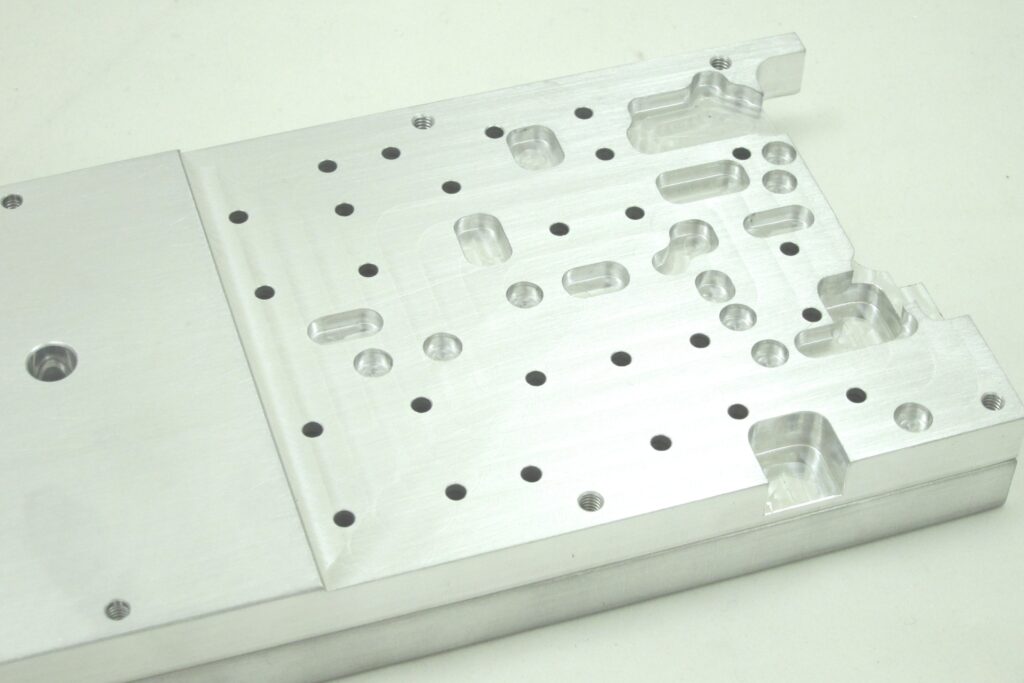

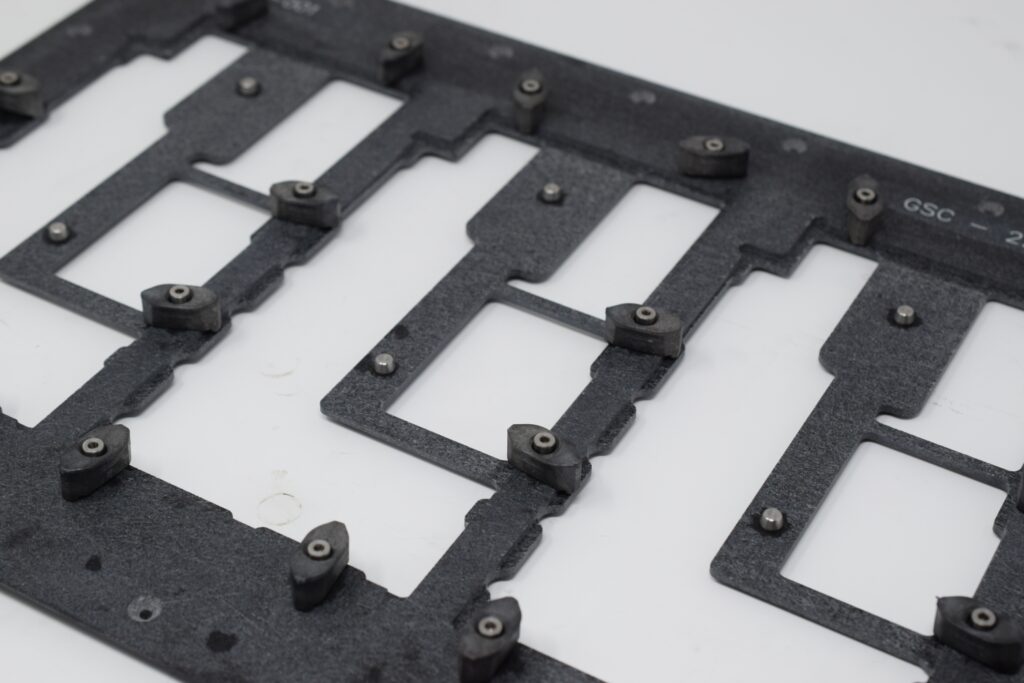

SMT Process Carriers

GSC fixtures accurately locate and support the PCB through all stages of the SMT process to insure that SMT components are properly located and soldered properly. After the initial setup, each fixture can be designed to function without operator handling.

Printer Plates

Using GSC’s printer plates to support the PCB during the screen printing process provides consistent results and reduced defect rates. Setup times are also minimized and throughput is increased.

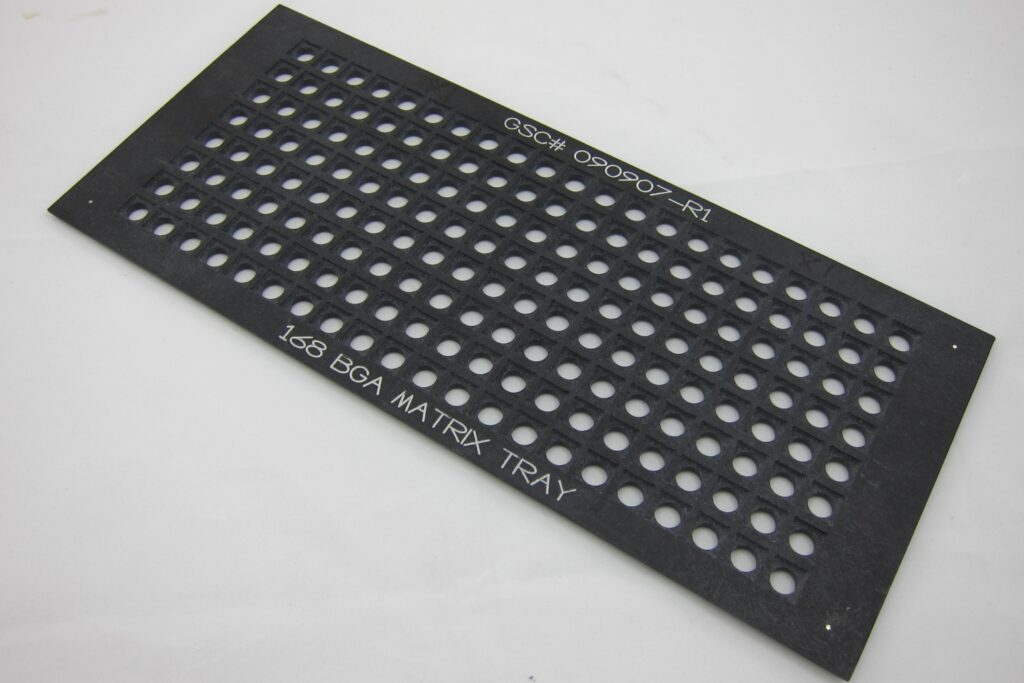

Matrix Trays

Using matrix trays insures safe handling, increased line speed and repeatable component placement. Each tray is able to hold components of varying sizes and is ideal for non-standard components.

AOI / X-Ray Carriers

GSC fixtures accurately support the PCB through all stages of the AOI/X-Ray process.