PCBA TOOLING

Get High-Quality PCBA Tooling for a Precise Assembly

Assembling your printed circuit boards needs to be done with care and precision. The process begins with quality PCBA tooling. In order to ensure your circuit board will function to the best of its ability, your PCBA tooling needs to be manufactured with skill and precision.

At Garland Service Company, we have been creating PCBA tooling for decades. We have honed our skills to provide our clients with the tooling they need to complete all assembly, inspection, and testing needs. Contact us today to get started!

The GSC Difference

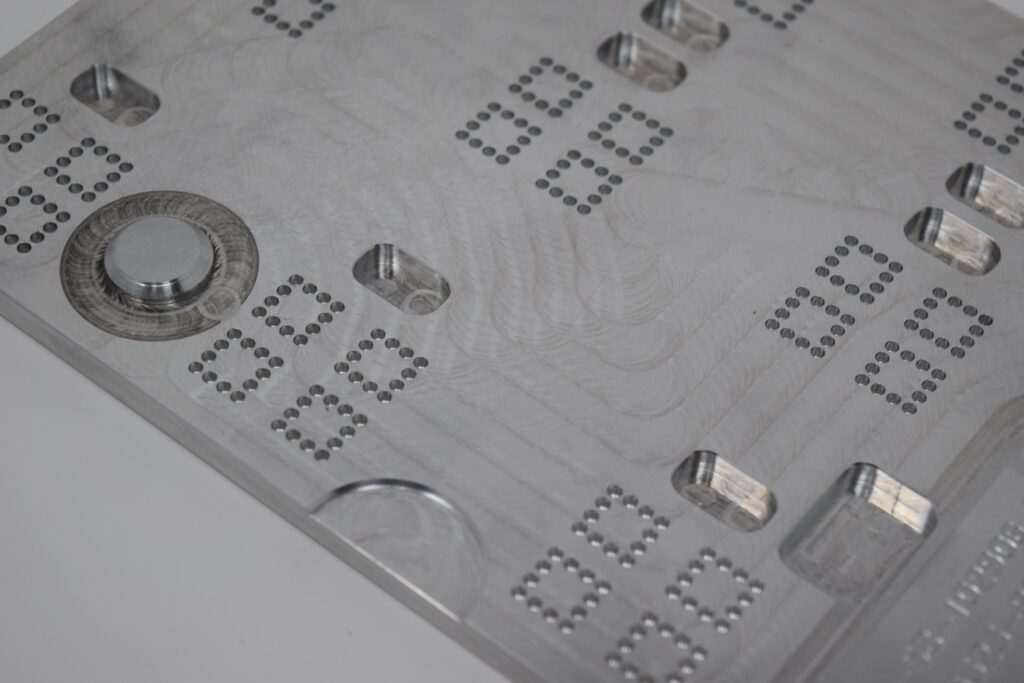

GSC has decades of experience designing and manufacturing PCBA tooling. This wealth of experience has led us to develop several proprietary design and manufacturing processes to ensure all pallets and tooling are of the highest quality. We have an internal proprietary component library containing tens of thousands of components. This ensures GSC can find the correct component and design the tool around accurate part numbers. The tool library also allows us to use our Individual Component Analysis approach which translates to wider openings for thru-hole connectors and significantly less material removed. Less material equals longer-lasting pallets. These tools allow us to cut down on the back and forth during the design process which means a more certain delivery time to keep your production lines running.

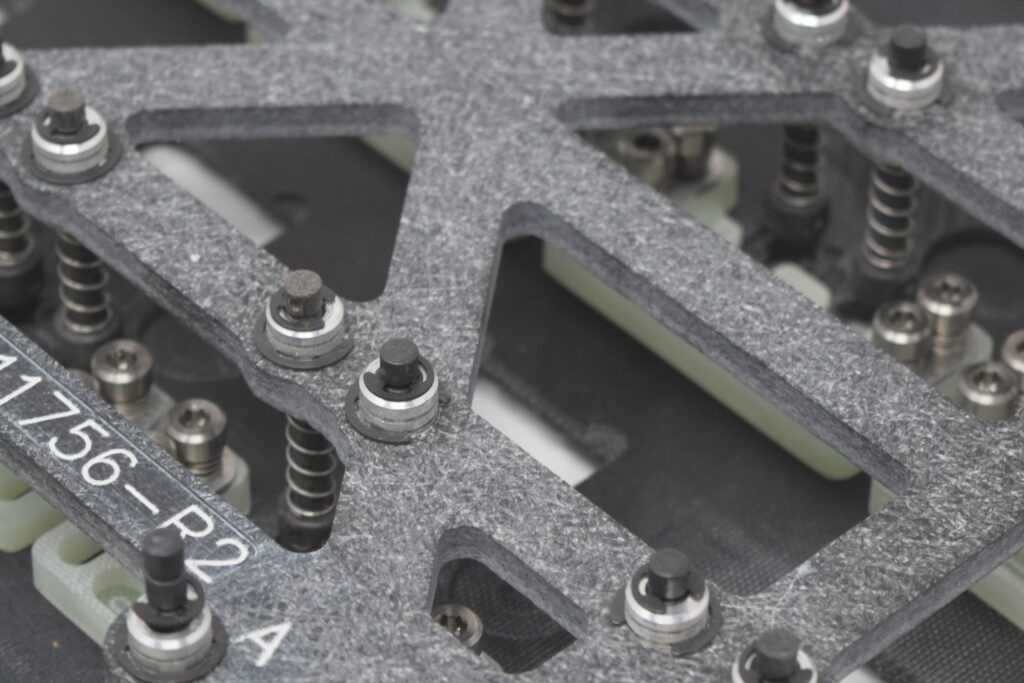

Our wave solder fixtures provide support during the wave soldering process, reduce defects, create thermal protection, and more. We can provide you with wash baskets, titanium stiffeners, workboard holders.

Selective solder fixtures are a cost-effective solution for consistent joining quality. Our selective soldering fixtures hold tight tolerances and decrease defects. Whether you need selective solder nozzles or fixtures, you’re covered.

Whether you need to mount electrical components, scan and test for functionality failures, or find hidden defects, we can easily provide you with the tooling you need to make it happen.

Press fit tooling ensures your PCB is properly supported and aligned during the insertion process. We can supply you with support plates and top tooling to ensure the proper insertion of your circuit.

Protect your PCBs from moisture and other environmental conditions with conformal coating from Garland. We can apply this protective coating manually or by using fixtures to hold the circuit board in place.

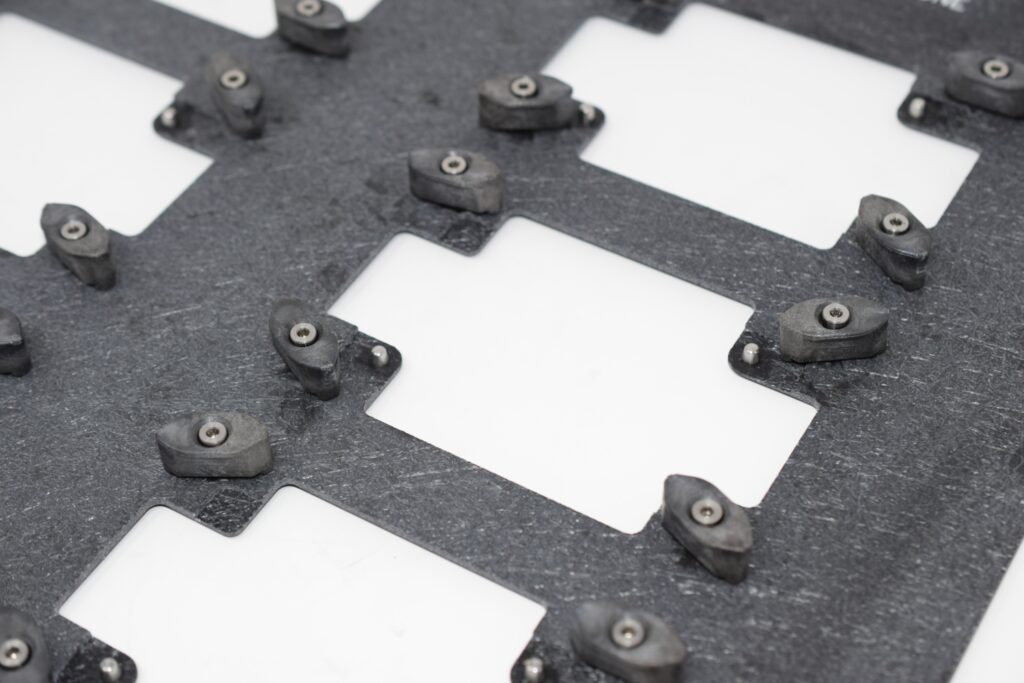

Whether you need simple or complex specialty tooling for your PCBA, we are here to help. Our team of problem solvers can conceive, engineer, design, and manufacture your specialty PCBA tooling.

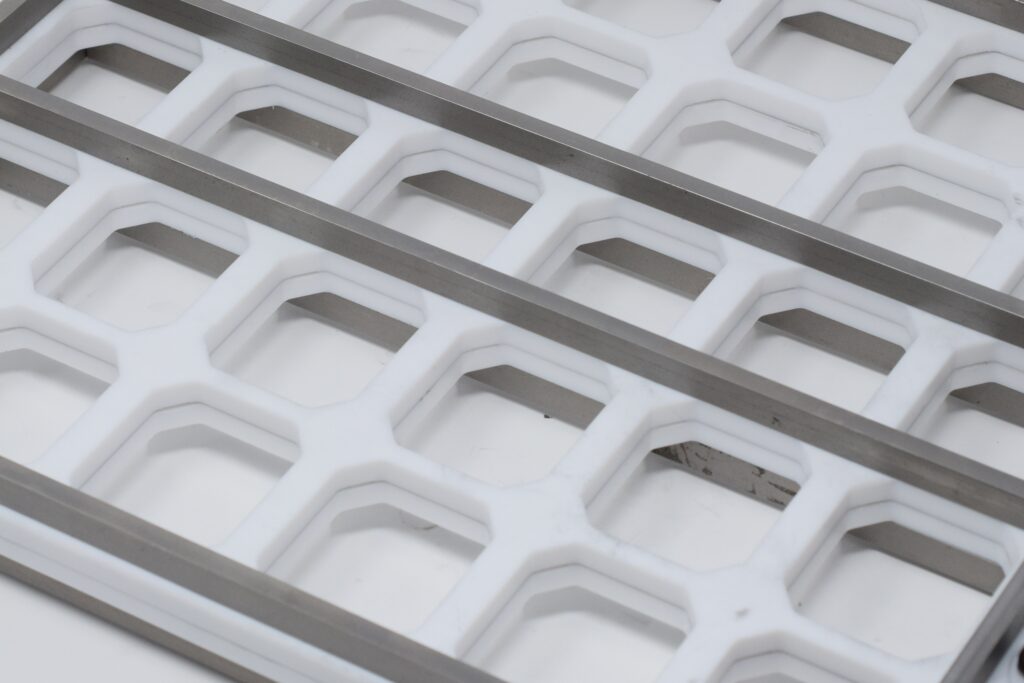

From proper PCB support to accurate locating of the PBC to eliminating PCB damage, router fixtures provide various benefits to your project. We can create fixtures with multiple materials or configurations in order to fit your machine.

The materials we use for our PCBA tooling are lightweight, easy to handle, have good chemical and heat resistance, and can withstand repeated use. We carry various different clamps and hold-downs to meet all of your requirements.

Get Started Today with Garland

If you are in need of PCBA tooling, Garland Service Company is here to help. We can create whatever you need to make sure your circuit board assembly is as efficient as possible. With decades of experience and the ability to problem-solve for you, we can tackle even the most complex and precise of projects. Contact us today to get started.