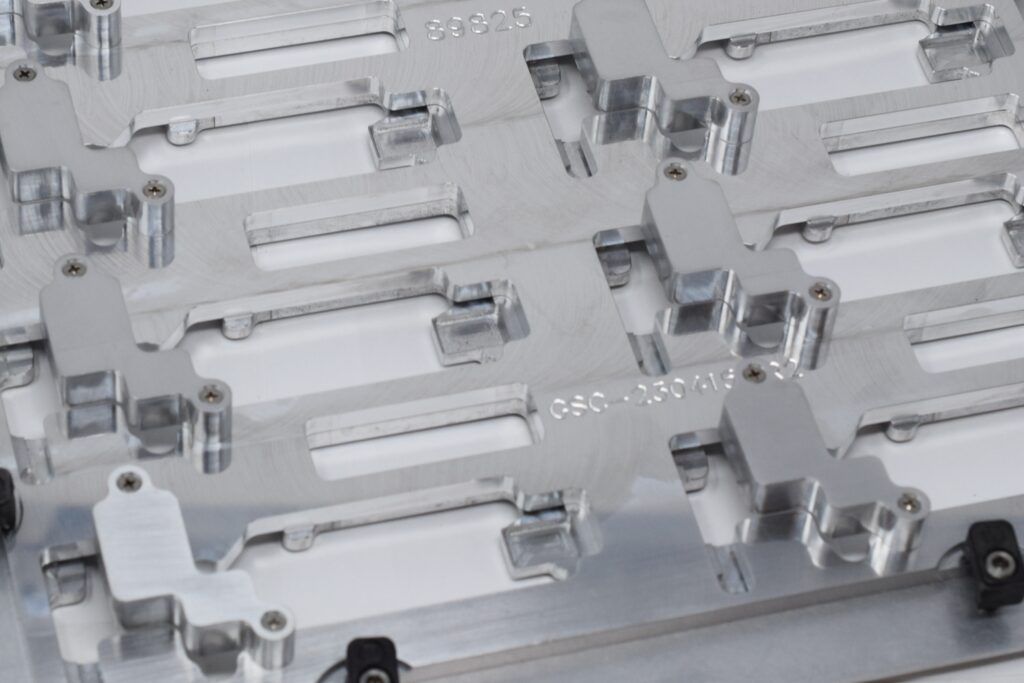

Material and PCB Hold-downs

GSC uses a variety of materials as fixture bases and other pieces. Most of the materials used have the following general characteristics. See the links below for technical data from some of the manufacturers.

Materials

- ESD materials protect sensitive components.

- High strength to withstand repeated use.

- Lightweight, easy to handle.

- Withstands high temperatures required for PCB processing without warping or delaminating.

- Low heat absorption allows quicker operator handling and cycling.

- Chemical resistance ensures long fixture life.

- Resistance to thermal shock allows retention of dimensional stability and flatness.

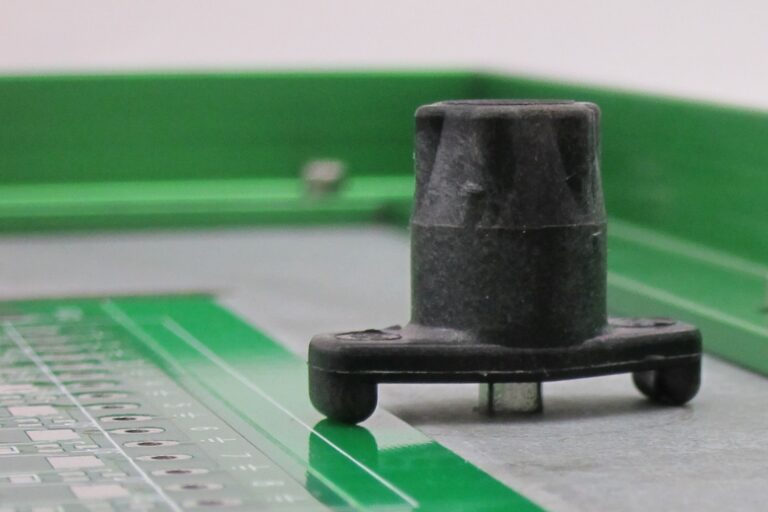

#0 Clamp

The “standard” PCB hold-down. Spring-loaded, rotates 360 degrees. Rounded feet always maintain downward pressure on PCB. Design provides the ability to hold two PCB’s per hold-down. Easily rotated by hand, or by using our special hold-down tool designed to make it easy for operators wearing gloves.

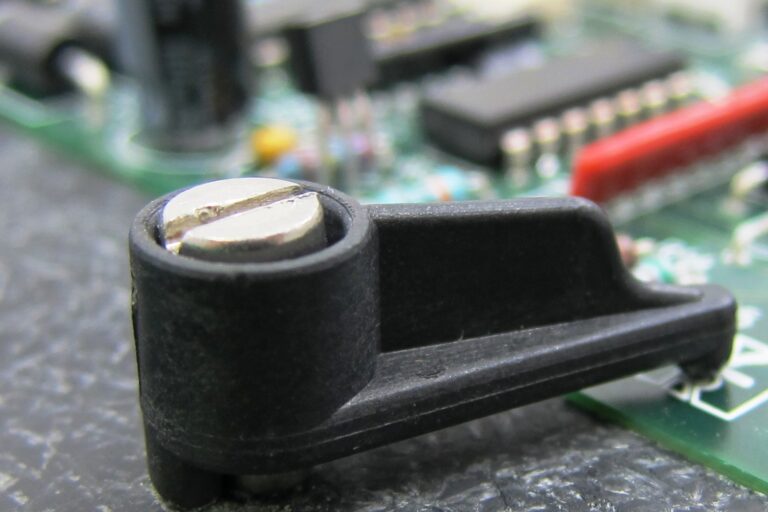

#1 Clamp

Spring-loaded. Rounded foot always maintains downward pressure on PCB. Used where space requirements do not allow full 360-degree rotation. Easily rotated by hand, or by using our special hold-down tool designed to make it easy for operators wearing gloves.

#3 Clamp

All purpose clamp that can be used for most solder pallet applications. Two rounded ends and ergonomic design to allow for easy engagement/disengagement from PCB. Spring and shoulder bolt allow for full 360 degree rotation and for consistent pressure on PCB at all times. This is considered the “next generation” of our #0 clamp and will slowly phase out that design.

Puller Clamp

Spring-loaded, below-surface PCB hold-down for SMT applications. Locating pins in the puller engage into tooling holes in the PCB. The only choice for thin board or flex applications. Locates accurately and repeatedly for screening and placement processes.

Pusher Clamp

Spring-loaded, below-surface PCB hold-down for SMT applications. A great choice whether or not tooling holes are available in the PCB. Force is applied to the edge of the PCB. Locates accurately and repeatedly for screening and placement processes.

Corner Pusher Clamp

Spring-loaded, below-surface PCB hold-down for SMT applications that is primarily used for smaller PCB’s.

Slider Clamp

Sliding design retains PCB in pocket without applying downward pressure.

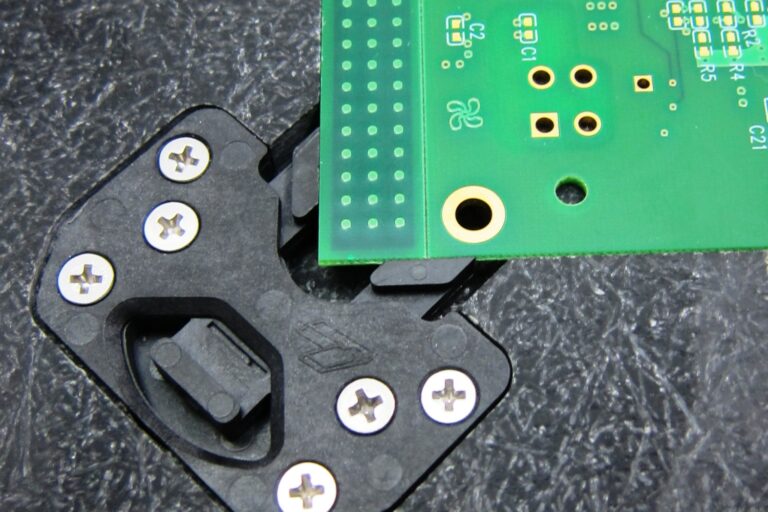

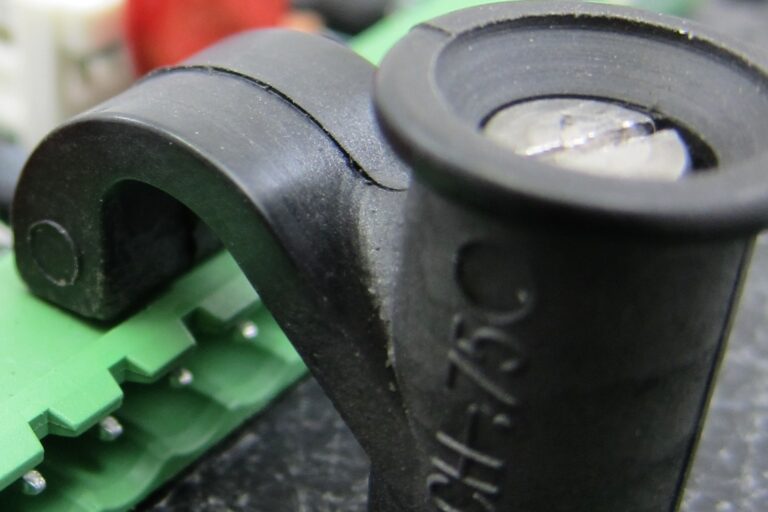

CH Series Hold-Down

The “standard” spring-loaded component hold-down. Keeps components firmly in place. Fully rotational. Available in ¾”, 1″, 1 ¼”, 2″, and 3″ lengths.