Conformal Coating

Conformal coating material is applied to PCB’s when they need to be protected from moisture and other conditions in the environment. Applying a protective coating may be performed manually or with the use of fixtures that hold the PCB during the coating process. Coating PCB’s manually is time consuming and can result in inconsistent coating application. Coating PCB’s by using fixtures significantly reduces labor costs and cycle times while increasing the consistency of the coating application.

Conformal Coating Benefits

- Reduce labor costs required by hand masking operations.

- Prevents uneven coating by evenly supporting PCB.

- Reduce cycle times and increase throughput by including multiple PCB’s in one fixture.

- Able to process any shape PCB through conveyor environment.

Conformal Coating Features

- Designed to minimize coating build-up between PCB and fixture.

- Designed with accurate board locating features.

- Fixture designed to allow for the coating both sides of fixture without reloading PCB.

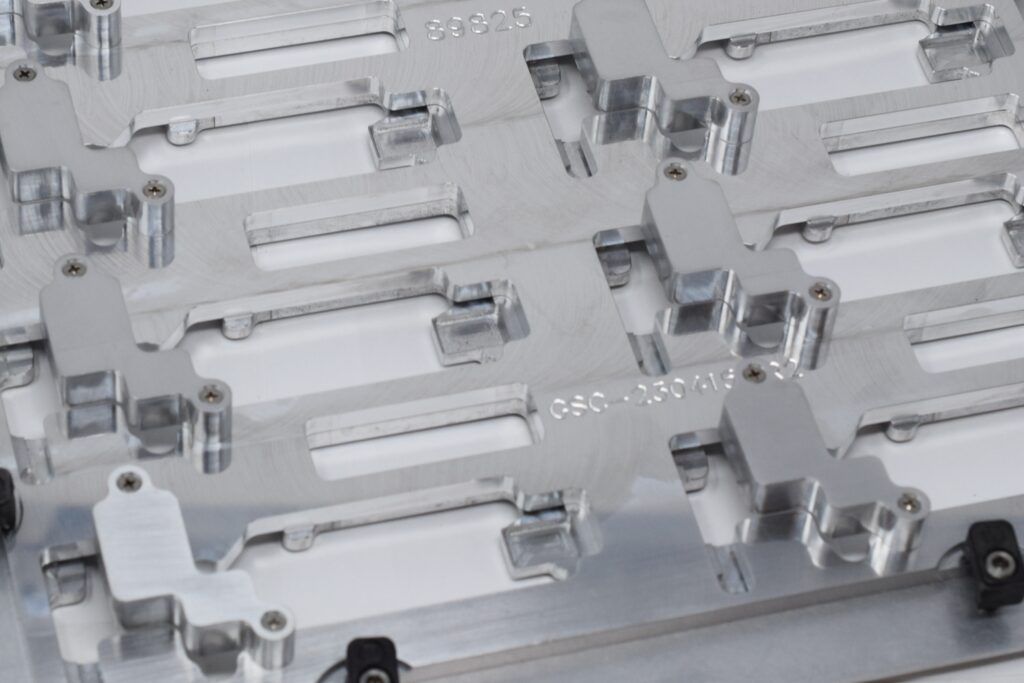

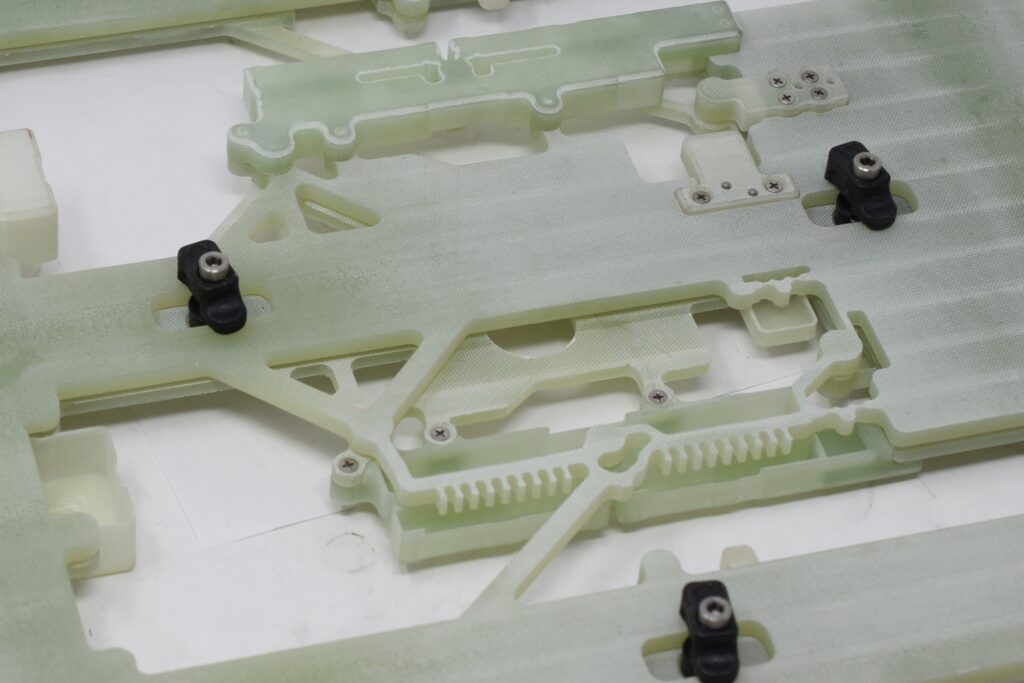

- Made from aluminum or composite materials with multiple types of coatings available.